I started PowerCartel because I was interested in reusing lithium ion batteries, and I recognized that people in a variety of enthusiast communities with the same interest in li-ion reuse were missing opportunities to learn from eachother. As I thought more about the subject, I realized that there were also huge opportunities in developing markets, where labor was relatively cheap, and steady sources of electric power were hard to come by.

It wasn’t a surprise then when I came across a paper by researchers at IBM India on their pilot project to reused lithium batteries to provide economical lighting and power for poor citizens of India.

The paper, titled “UrJar: A Lighting Solution using Discarded Laptop Batteries” was authored by Vikas Chandan, Mohit Jain, Harshad Khadilkar, Zainul Charbiwala, Anupam Jain, Sunil Ghai, and Deva Seetharam of IBM Research India, and Rajesh Kunnath of Radio Studio. It makes a strong case for lithium battery reuse given the poor economics of recycling, makes an assessment of the yield of useful cells from discarded lithium battery packs, and describes the design and field testing of the UrJar.

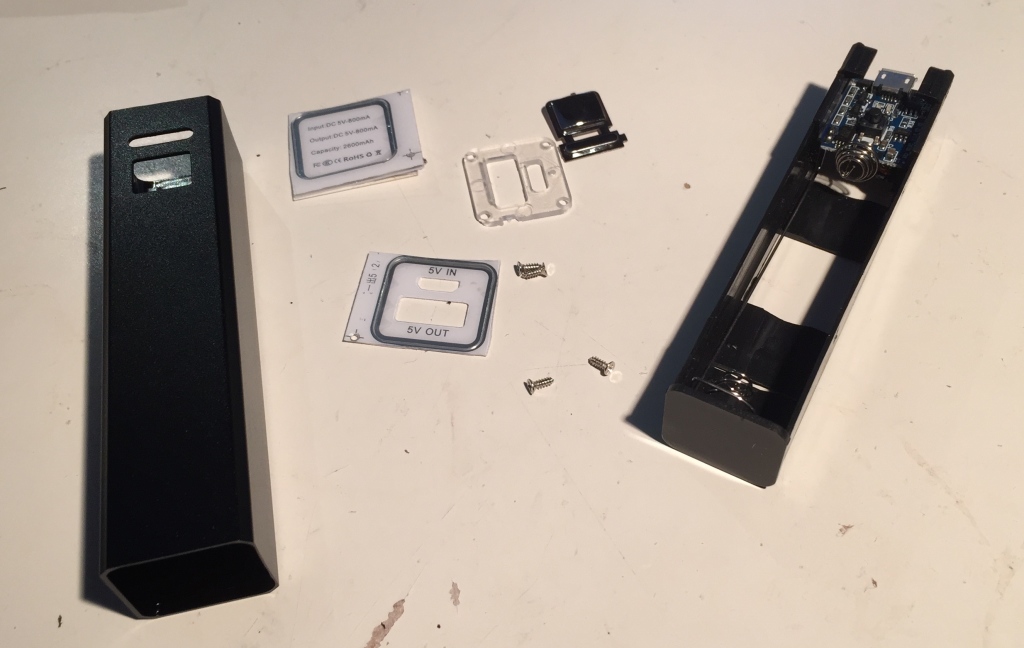

The UrJar is a device powered with reclaimed lithium ion batteries. It provides power ports a LED light, and other devices like cell phones and/or a portable fan. There is circuitry to recharge the internal batteries, and provide the required power to the LED and external devices.

I’d challenge some of the design decisions in their prototype. They use a 3s2p (3 series, 2 parallel) topology for the cells, which requires proper cell management for safety, as well as longevity. The prototype omits this circuitry. Including it will impose an additional cost. A 1s6p configuration would provide more safety in a simpler configuration. It would also allow a wider selection of inexpensive charging chips or even complete charging modules. The downside might be slightly lower efficiency in the circuitry to power external devices, but that could be offset by adding more cells, with the expense offset by the savings from commodified charging and power conversion modules. They might even be able to use existing commodity cases and electronics on the market for reusing 18650 batteries.

Its also worth considering that the laptop packs the source the cells from already have the circuitry to properly manage series packs by avoiding over-discharge of one bank, and balancing all of the banks during charging. There might be a viable approach to using the intact packs (when all the cells are of good quality), or reusing the circuit boards (when a working pack has to be assembled out of cells recovered from multiple packs).

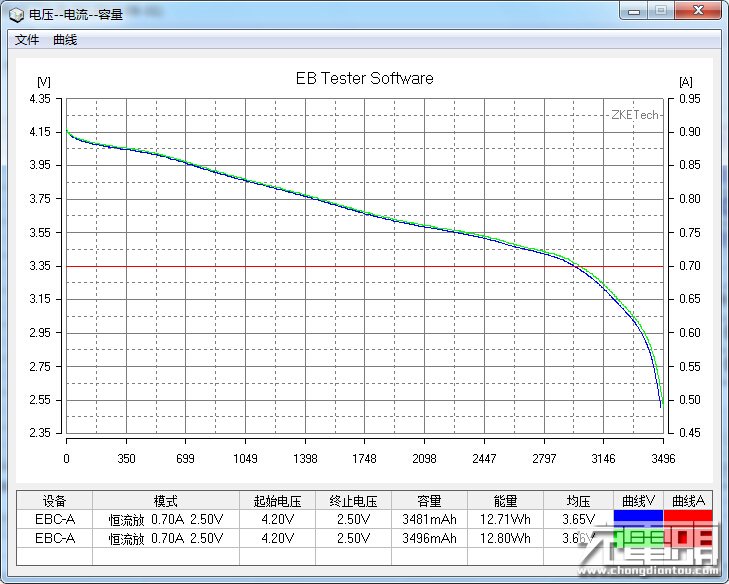

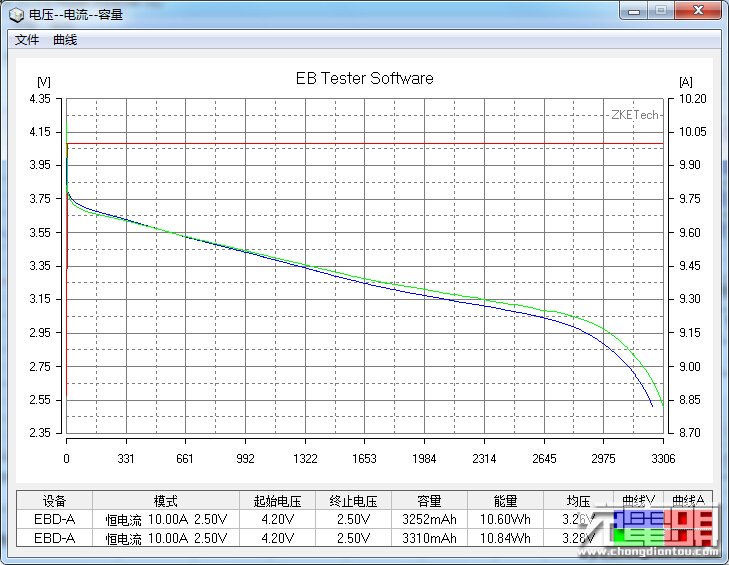

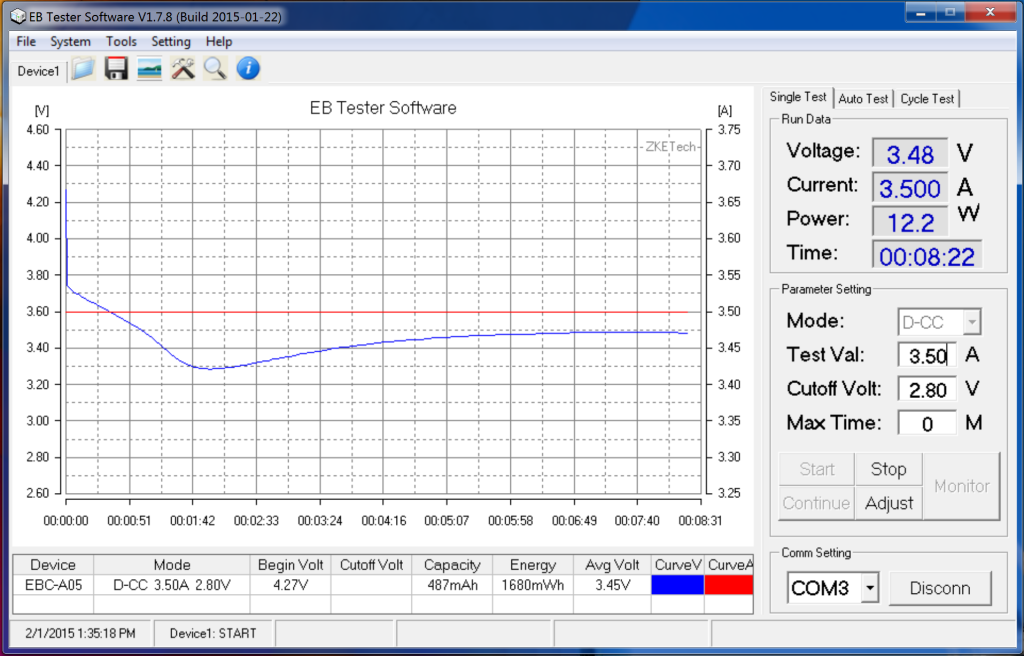

I also have a quibble about their description of the Thinkpad battery packs used in their study. They describe them as 6 cell packs rated 85Wh each, and being at least three years old. This seems unlikely. The cells would have over 14Wh each, which works out to 3,800 mAh at 3.7v nominal cell voltage. 3,800 mAh 18650 cells weren’t available 3+ years ago. They aren’t even available today, so far as I know. Last I checked, the 3,400 mAh cells from Panasonic held the record.

These criticisms are all relatively minor though. The important issues aren’t the specifications of a prototype battery pack, or the design and sourcing choices made for the hardware. What is important is that these batteries have residual economic value, and even more importantly, figuring out the right mix of cost, features and services for a product that will help poor Indian consumers better their lives, and stimulate local industry. On these fronts, the authors seem to have done good work. I also appreciate their bibliography, which will give me a head start on some literature research I planned to do. I’m in the process of drafting a letter to the authors, congratulating them on their good work, and inviting them to join the community I’m trying to start here around PackProbe, and other tools for reusing lithium ion battieries.

Their work has attracted plenty of other attention of late, I suspect the result of some savvy PR on someone’s part. IEEE Spectrum has a summary, as does the BBC News, and Technology Review.