Earlier this year, a series of rumors and reports emerged that Apple may (or may not) be making serious investments in developing an electric vehicle. Taken as a whole, the rumors and reports are intriguing, if not convincing, but there are also plenty of alternative explanations for the circumstantial evidence.

This isn’t a site about Apple though, or cars, or technology in general, it is about batteries, and my purpose with this post is to note some interesting tidbits about Apple and batteries that have emerged in the attention to the Apple Car.

First, Apple has been recruiting people from battery companies. They are being sued by A123 for hiring some of their employees. A123 is a battery company specializing in Lithium Iron Phosphate (AKA LiFePO) cells. The employees in question were A123’s former CTO, Mujeeb Ijaz, and various engineers responsible for developing and testing lithium ion batteries. A123’s earliest design wins were in batteries for tool packs, but there current focus is squarely on providing batteries for the growing electrical vehicle market. They also faced bankruptcy recently, so it is not surprising that their employees were open to be recruited to working on battery technology at Apple, whether or not those batteries will be used in electric cars.

In the complaint, A123 claims that Apple has hired employees from other li-ion battery companies A123 has ties to, including SiNode Systems, Samsung, Toshiba, LG, and Panasonic.

Apple is clearly interested in advancing the state of the art for battieries in service of its publicly known product lines. The design of the upcoming Apple Watch seems strongly influenced by the issue of battery life and the new MacBook goes to extraordinary lengths to maximize the volume of the device occupied by the battery.

This isn’t anything new for Apple, but they’ve gone to extraordinary lengths with the new MacBook. Apple used to use battery packs built around the cylindrical, metal encased, 18650 cell, but about 10 years ago, they were pioneers in the use of pouch cells, which use a plastic pouch, rather than a metal can, and are shallow rectangles, rather than cylindrical. Apple’s move to pouch cells allowed thinner systems with less space wasted in the baps between cells. The followed up by forgoing field-replaceable batteries, for battery packs installed in the main cavity of the computer. The space saved was used to increase battery capacity. The Retina Macbook Pro went even further, gluing the cells directly to the laptop case. It also used a mix of cell sizes.

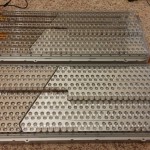

The latest MacBook goes even further. The logic board is tiny compared both to past Apple laptops, and the batteries, which occupy most of the volume and floor-plan of the computer, are unprecedented. The cells aren’t simple rectangles, they have rounded and notched edges.

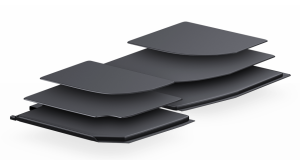

For even more battery density, they are stacked in a terraced fashion.

Whether an Apple car makes it to market, if it is being developed at all, I am certain that Apple wants to stay on the cutting edge of battery development, whether in packaging, chemistry, management or manufacturing. Whether it is Apple, or its suppliers in the lead, Apple needs people who know all about the development, manufacture, and use of lithium ion batteries. It is no surprise they’ve been hiring them.