While trying to find details of what’s inside HPs extended runtime batteries, I came across video shot by Tom’s hardware of a press junket / meet-and-greet with Dr. John Wozniak from HP talking about what goes into designing and HP’s battery packs.

It’s from spring of 2012, which makes it a bit dated in some regards, but I still found it informative, particularly since most of the battery packs I’m getting are of a similar vintage.

Some things I found interesting:

- Relative to 18650 cells, prismatic LiIon are ~1.4x more expensive, and pouch packs are 2x more expensive for the same capacity.

- At the time, 18650 cells were clearly HPs focus for price/capacity. They were, however, using prismatic cells and pouch-packs for thinner form factors.

- Pouch cells are relatively easy to get 1000 charge cycles from because they can expand and contract as needed when being charged and discharged, reducing the pressure that degrades the electrodes. The downside is that cells can also expand due to gas generation, which can damage the pack and/or other components.

- At least for the products being discussed, HP seemed to be transitioning from prismatics to pouch packs.

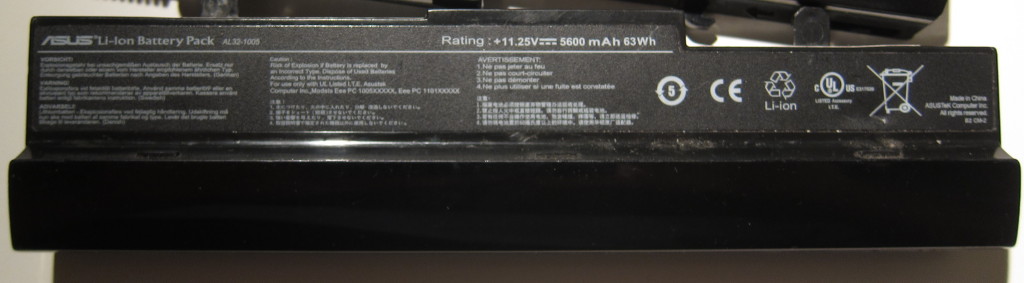

- Safety regulations limit companies from stuffing more than 100Wh into a single battery pack. This, combined with improved capacities, have lead to the demise of 12-cell extended runtime packs.

- At the time, HP was using LG 3000 mAh cells for their high-capacity 18650 packs.

- Apple shouldered the growing-pains of getting pouch-cell pack design and manufacturing right.

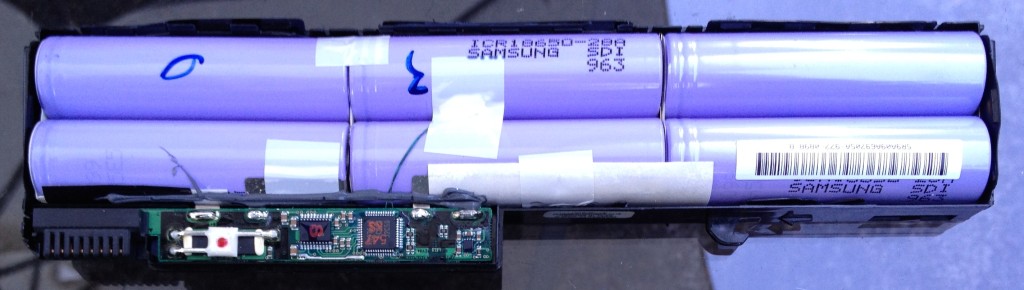

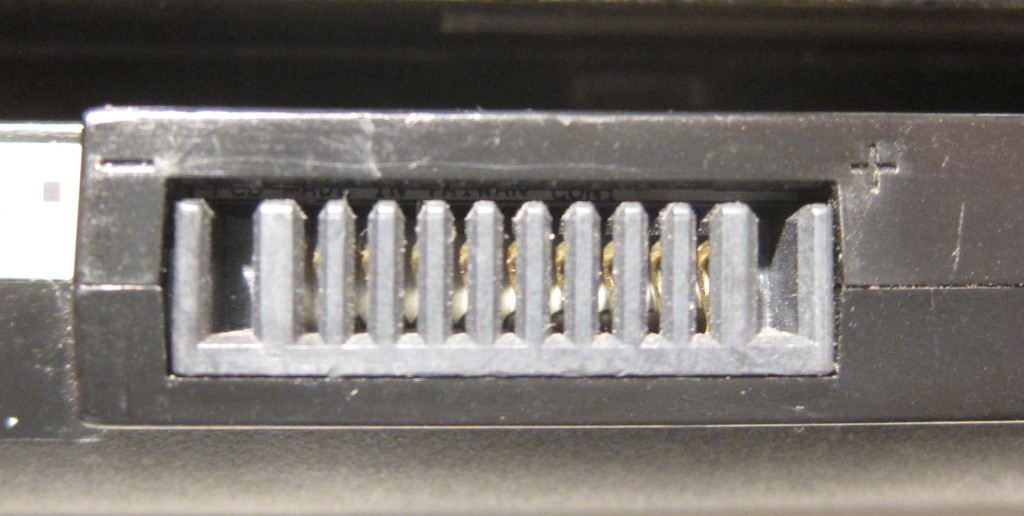

- Because the cells are a commodity, HP tries to distinguish its packs on quality, reliability and manufacturability. This has led them to use conformal coatings on circuit boards to protect against shorts and corrosion. They’ve also switched from wires to flex circuits within the packs for improved reliability and their pouch-cell packs have moved to welding the cell contacts directly to a PCB.

- Their primary suppliers are Panasonic, LG, Samsung.

- Among Chinese cell manufacturers, they’ve tried to work with a few, but the economics haven’t worked out. B&K is a qualified supplier for some of their packs, but HP doesn’t ship many of their cells.